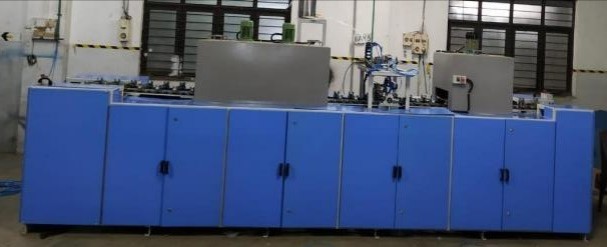

Single Station Conveyorized Horizontal OD Spray Machine (Rod

Type)

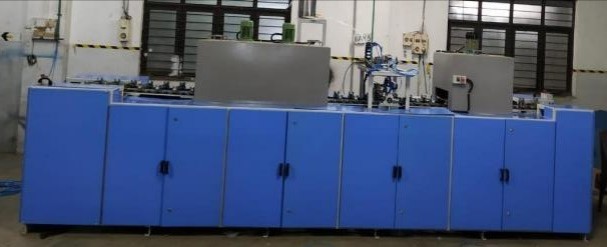

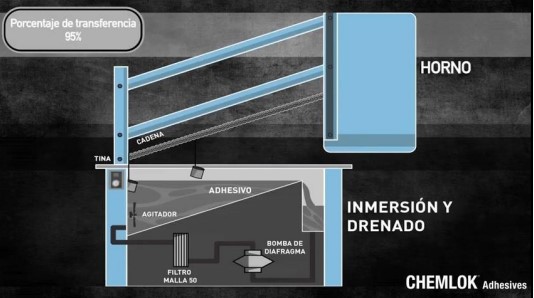

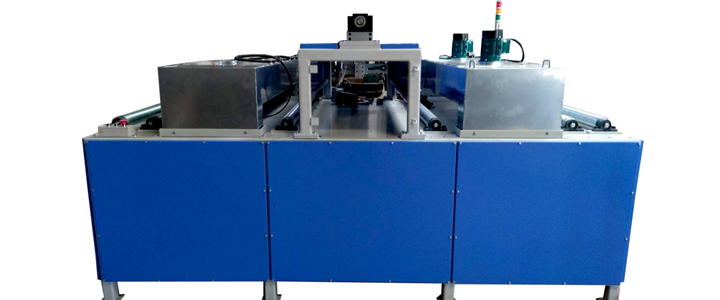

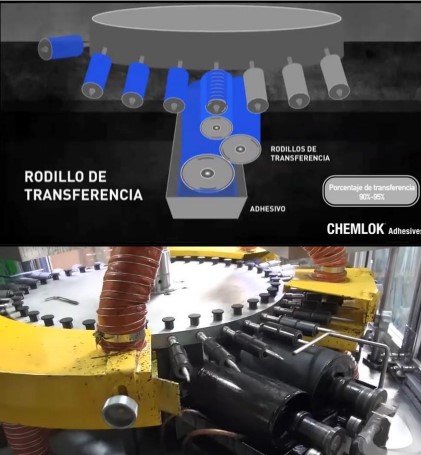

- This machine is designed to apply adhesive viz.

Chemlok on metal components

before molding. Possibility of extension of heater is possible to achieve the

desirable

drying of components. The conveyor chain provides more strength and stability in

the

overall process. The machine has a good accuracy with great consistency without

hampering the quality of work.

Features:

Robust Mechanical Powder Coated Structure

Electrically Powered Chain Conveyor.

The conveyor is basically driven by AC Motor (Confirming IS: 325) & the speed

controlled by VFD of reputed make confirming all electrical standards.

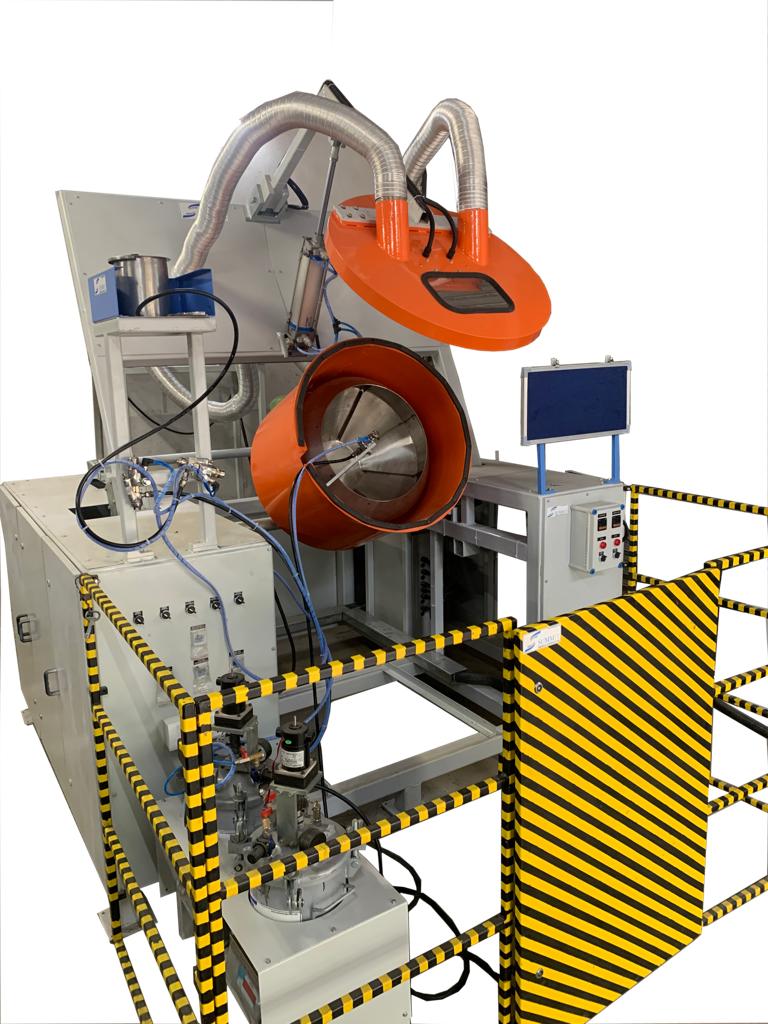

1 nos. of electro-pneumatically operated job clamping & rotating system.

Pneumatically operated Spraying System.

Controlled spray of the Primer & Secondary Coat for even & desired coat

thickness.

1 nos. of Heater Chambers with independent Temperature Control & Blower for

circulation of Hot Air. 2.3.8 10-liter SS Container for Primer & Secondary Coat.

Separate Control panel consisting of PLC, HMI, Drives & Audible & visual

Alarm System.

Separate Pneumatic Panel for pneumatic components for easy traceability &

maintenance.

Level indicator based on weighing scale to indicate level of paint container using

an audible and visual alarm.

Facility to spray 1way & 2way at either of the station1.

Machine operation totally programmed by PLC.

Tower Lamp Indicating the Machine Status.

Fault Diagnostic feature which displays the exact error all possible faults on the

HMI, helping in easy Maintenance.

Product Parameters:

| 1 |

Heaters |

3 kW & 6kW

|

| 2 |

Electrical Power Supply |

415V, 50Hz, 11Kw

|

| 3 |

Pneumatic Air Supply |

4-6 bar

|

| 4 |

Electrical Heating Chambers (optional) |

2 (3kW/6kW)

|

| 5 |

Spraying Area |

405 mm

|

| 6 |

Pressure feed auto gun |

1 (Iwata Make)

|

| 7 |

SS Chemlok containers |

10 liters

|

| 8 |

Cubic Feet per Minute (CFM) |

13

|

.png)