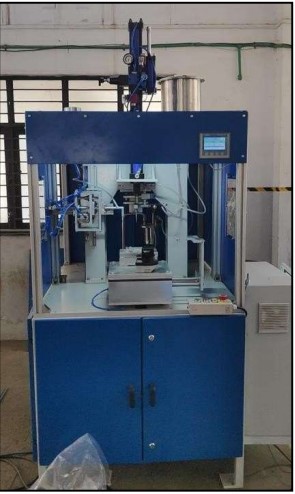

Impact and Durability Test rig

- This test ensures us about the toughness of the PU

Bump stopper as material's toughness

is a factor of its ability to absorb energy during plastic deformation. This

setup is

designed to carry out durability test of PU bump stopper used in automobile

applications. Facility of impact durability test is also provided by changing

stroke to

60mm. In short Impact Testing of metals is performed to determine the impact

resistance

or toughness of materials by calculating the amount of energy absorbed during

fracture.

Features:

Total setup is mounted on a strong and sturdy fabricated frame structure made

out of M.S square tubes and plates.

a. Overall size: 0.8m x 0.6m x 1.5m height.

The stroking mechanism comprises of:

a. 5 HP eared motor with 120RPM output speed provided with VFD.

b. Intermediate bearing block with eccentric one side and geared motor coupling

on other side.

c. Eccentric mechanism with manual adjusting screw and locking arrangement.

d. Range: 0 – 30mm (Total stroke up to 60mm) for bump stopper impact and

durability test.

e. Range: 0 – 90mm (total stroke to 180mm) for Dust cover durability test.

f. Connecting rod with hard chrome shaft and linear bearings to transmit motion to

test component.

For Bump Stopper Testing:

a. Two jaw chucks for holding the stroking

fixtures for the test component with

central guide rod.

b. Top plate supported in tow hard chrome plated rods.

c. Bottom moving plate fitted to eccentric mechanism provided with two linear

bearing guides for proper vertical movement.

For Dust Cover Durability Testing:

a. Adjustment in eccentric mechanism for setting stroke up to 175mm.

b. Two guide bars for uniform movement with test component bottom clamping

arrangement.

c. Adjustable top plate with top clamping fixture for test component.

Electrical control panel.

a. M.S control panel duly powder coated.

b. Digital speed frequency indicator - Range: 0 – 120 RPM or 2 Hz.

c. Digital cycle counter - Range: 6 digits adjustable.

Other electrical accessories such as Contactors, MCCB, Push buttons, indicators

lamps etc.

Product Parameters:

| 1 |

Overall size |

0.8meter x 0.5meter x 0.8meter height

|

| 2 |

Electrical Power Supply |

415V, 50Hz,6Kw

|

| 3 |

Pneumatic Air Supply |

4-6 bar

|

| 4 |

Capacity |

500 Kg

|