- This machine series will dramatically boost

productivity, while lowering production costs.

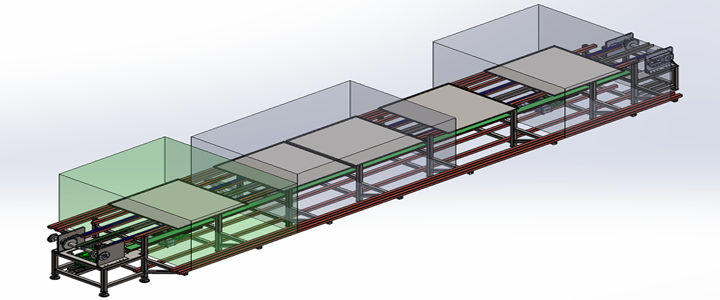

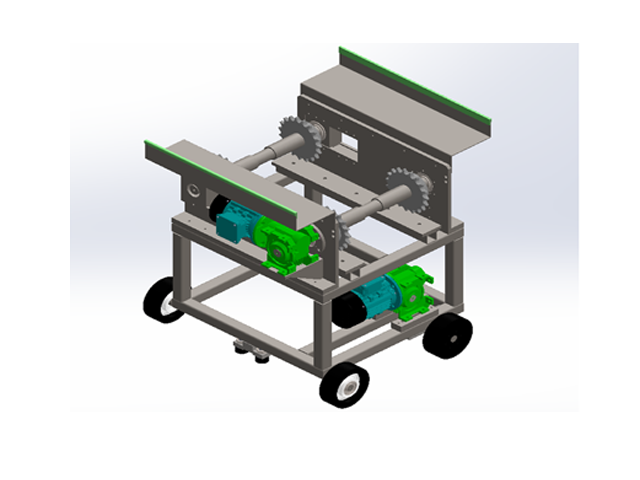

- Rotary Indexing Machine– Typically the most efficient

way to get high production volumes and to produce parts at a high speed is to

use a rotary or linear indexing machine. Whether it is a rotary indexing dial or

a linear power and free conveyor,

simultaneous actions on several parts the cycle time is reduced.

We design and build a machine that allows you to assemble complex parts at a

faster rate.

We develop Indexing SPM (Linear or Rotary) as per customer’s process

requirement.

Our developed Indexing SPM (Linear or Rotary) can be-

Fully Automatic or Semi-Automatic.

Have combinations of hydraulic pneumatic systems.

Smart PLC controlled

- Semi-Automatic indexing machines are

best suited for lower volume and/or oddly shaped assemblies where automatic

parts feeders would not be cost effective. A semi-automatic machine can also be

designed as a base machine for a fully automated assembly where product volume

is expected to rise in the future.

- Fully automatic machines are best

for higher volume products which would benefit from reduced labour costs. They

are also a good option for assembly in line with moulding operations.

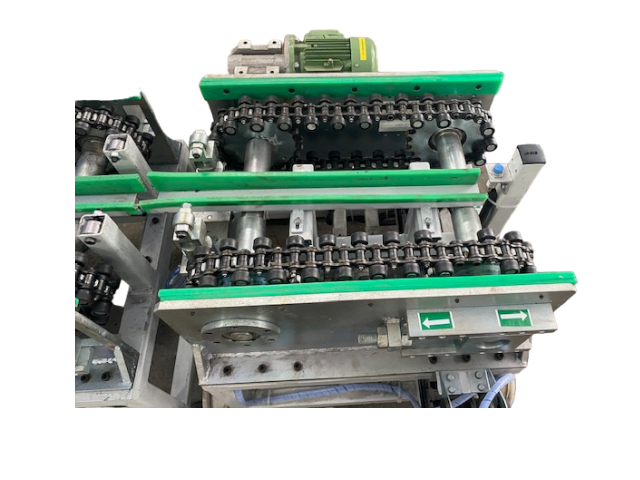

Specifications:

| 1 |

Frame Doors and Covers |

MS (powder Coated)

|

| 2 |

Power Operated |

Electrically

|

| 3 |

No. of Job Fixtures |

24-30

|

| 4 |

No of spraying station |

2 (pneumatically operated)

|

| 5 |

Control panel type |

PLC with HMI, Variable Frequency drive

|

| 6 |

Hot air blowing system |

3 (3kw each), temperature control, circulation fan

|

| 7 |

Cycle time |

5-6 sec

|

| 8 |

Pressure feed tank |

2 (9 liters each)

|

| 9 |

Exhaust canopy |

Yes (no blower)

|

| 10 |

Loading/unloading type |

manual

|