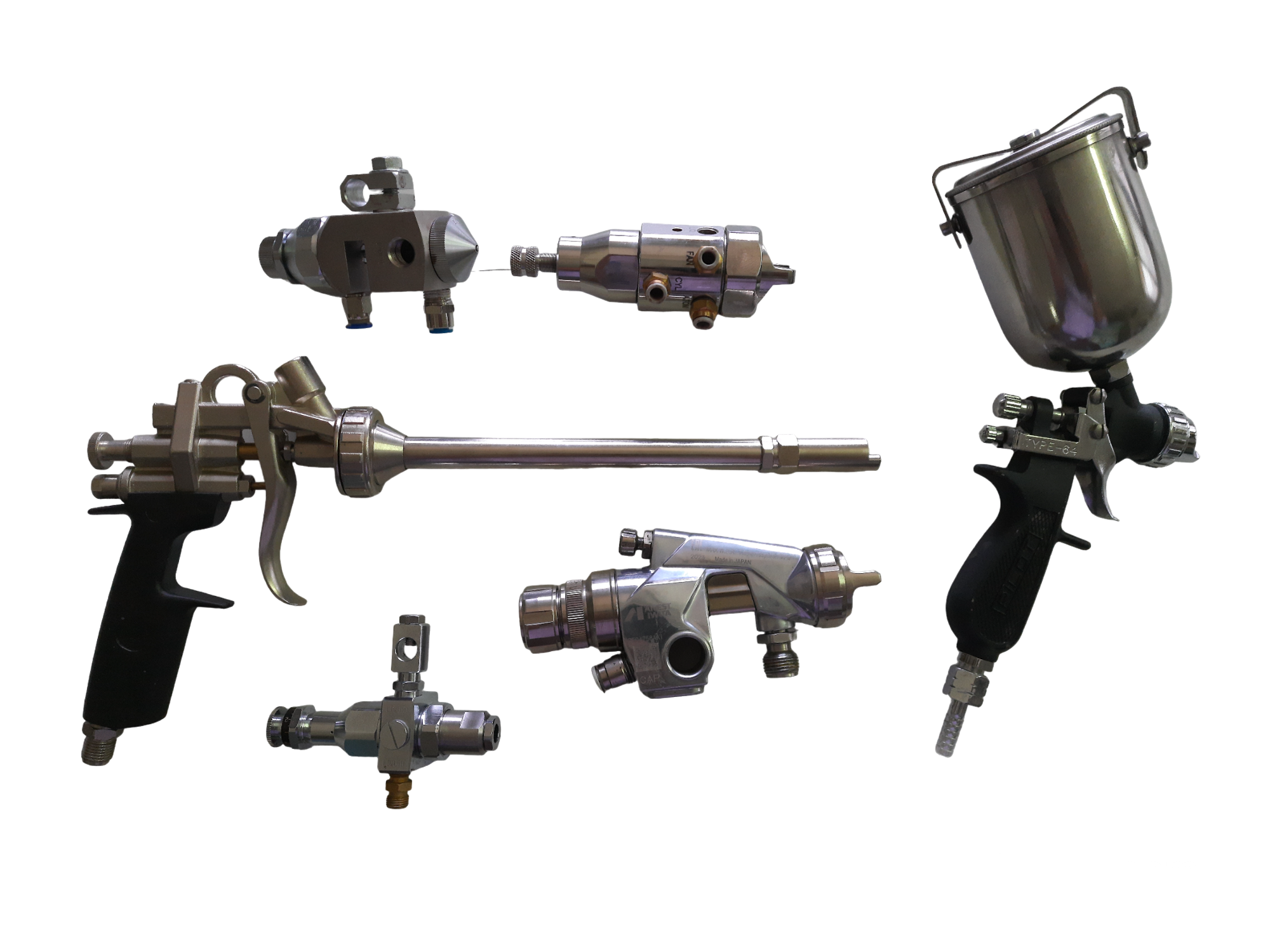

Spray Guns (Auto and Manual)

- We provide Compact size HVLP automatic spray gun which

is suitable for automated painting equipment and tools, reciprocators, or

robotic painting.

- These guns used in mass production spray application

in wide range of industries like Painting, Pharmaceutical, dyestuff coating,

Oil, Lubricating, Food industry, Rubber solution spray, Textile spray,

water-based materials/paints. Etc

- Guns to be used with water borne and solvent based

products.

- easy installation

Features:

robust construction,

minimum maintenance,

offers multiple mounting and spraying options,

perfect finish, corrosion resistance, high performance, dimensional accuracy

compact designs, and durability.

Technical Features:

| 1 |

Max. pressure |

4 Kgf/cm2

|

| 2 |

Standard Nozzle |

1.00-5.00 mm

|

| 3 |

Air consumption |

50 CFM.

|